Introduction to Supply Chain Management

Supply chain management is crucial, for the success of businesses, in sectors as it involves managing and improving all the activities related to producing and distributing goods. Starting from acquiring materials to delivering products to customers efficiently and cost effectively.

What is Supply Chain Management?

Managing the supply chain involves coordinating and integrating tasks across a companys supply chain network such, as planning production and logistics operations to enhance customer satisfaction by optimizing efficiency and reducing wastage.

Definition and Importance

Recent market analysis indicates that the supply chain management industry is expected to hit a value of $30..91 billion by the year 2026. Showcasing its role, in enhancing efficiency and spurring growth in companies.Lastly 83 percent of businesses are focusing on customer supply chains through prioritizing customer service,differentiated services well, as diverse fulfillment options.

Why Understanding Supply Chain Management is Crucial

The importance of grasping supply chain management cannot be overstated given its influence and operational advantages it offers businesses, with well functioned supply chains have experienced notably higher revenue growth than those facing supply chain challenges (79 percent vs 8 percent). Additionally 74 percent of industry experts in supply chain management are looking to boost their spending, in technology and innovation as they acknowledge the role these factors play in improving efficiency.

Global Impact and Efficiency

According to a survey findings unveiled that nearly half of the participants either lack insight into their upstream supply chain or can only see up to their suppliers level.The absence of transparency, in this area can result in inefficiencies and higher expenses, across the supply chain operation.Moreover the study indicated that over a third of supply chain leaders mentioned that their companies are already leveraging automation,AI and machine learning strategies to improve their supply chain management.

Purchasing and Supplier Selection

In the field of supply chain management (SC) procurement is vital, for securing the materials and resources needed for manufacturing operations by pinpoint the companys needs and wisely choosing suppliers capable of fulfilling those demands efficiently.

The Basics of Purchasing in Supply Chain Management

Procurement, within the realm of supply chain management involves a series of steps that kick off with pinpointing requirements. An in depth review of the materials or services for business operations or production processes to function smoothly and effectively in a sustainable manner. After these requirements have been defined precisely mapped out comes the pivotal task of supplier selection. A process that requires assessment of possible collaborators based largely upon their competencies and track record for dependability as well as how well they align with the overarching objectives of the organization, at hand.

The Importance of Supplier Selection

Choosing the suppliers is crucial, in supply chain management as it has an effect on key factors, like quality, cost effectiveness and dependability of supplies. Ensuring that suppliers adhere to quality standards is essential to guarantee that the materials or parts received meet the required criteria and enhance the quality of the end product. Considering costs is important to stay competitive and profitable while ensuring suppliers can provide a supply without interruptions.

Case Study: Supplier Selection in the China Market

In the market there are challenges and opportunities, for choosing suppliers in worldwide supply chains. One significant challenge involves overcoming gaps and language barriers when forming partnerships with suppliers from China. Nonetheless this market also provides chances for sourcing access, to a range of manufacturing abilities and the possibility of working together with forward thinking technology focused firms.

Holyale is a company that specializes in providing high-quality inspection and quality control services. Holyale’s supply chain management is a comprehensive and value-added service that includes supplier development, managing suppliers on behalf of clients, and supplier auditing.

In terms of supplier development, Holyale’s supply chain includes core manufacturers from most industries. They continuously develop relationships with these manufacturers to ensure competitive pricing and cooperation. This includes providing small MOQs, favorable pricing, quality samples, priority production, and faster delivery to help their partners be more competitive.

Managing suppliers, for clients is an aspect of the supply chain that Holyale acknowledges as vital for operations.The collaboration with suppliers ensures clients receive the products at competitive prices and on time.Holyale supports clients, in supplier management to spare them from dealing with suppliers and save both time and money in the process.

When it comes to supplier audits, at Holyale firms aid is to dodge complications with suppliers by conducting audits at the beginning stage; this assists, in verifying their authenticity as manufacturers and their capability to fulfill obligations while assessing their reliability as well.

Holyale’s supply chain management also includes on-ground sourcing services to support partners with supply chain management, quality assurance, and responsible sourcing. They also offer a 100% risk-free commitment, bearing all buying risks such as supplier fraud, quality problems, customs declaration challenges, and delivery issues.

Operations Management and Production

Operations management holds a position, in the field of supply chain management (SCN) contributing significantly to the running of production activities and the efficient use of resources.

Ensuring Efficient Production Processes

In order to make production effective and smooth, in operations management field different methods and plans are used. One of these approaches is manufacturing that concentrates reducing wastage and enhancing output by improving processes. Moreover just, in time ( JIT ) inventory control is adopted to simplify production by receiving supplies when necessary during the manufacturing process thereby cutting down surplus inventory expenses.

Ensuring production processes relies heavily on implementing quality control measures to maintain standards throughout various stages of production and promptly address any deviations, from quality benchmarks through thorough inspection and testing procedures. Moreover incorporating manufacturing systems enhances the ability to respond swiftly to shifts, in consumer demand and specific product customization needs.

The Role of Technology in Operations Management

In the realm of supply chain operations management technology plays a role, in improving efficiency and effectiveness. The integration of automation like robotics and advanced machinery simplifies repetitive tasks while minimizing mistakes and enhancing productivity. Tools, for data analysis allow for tracking of production indicators which aids in making informed decisions and addressing potential problems proactively.

Moreover,connecting Internet of Things (Io T)devices offers information, about how equipment performs,what maintenance it requires,and the patterns of energy consumption.This data driven strategy enables companies to allocate resources efficiently,reduce downtime,and improve productivity overall.

Operations Management in the China Market

The market, in China offers an evolving environment for managing operations in supply chains.The latest trends signal a move towards adopting manufacturing methods propelled by technological progress like 5 G connectivity and artificial intelligence.These advancements empower maintenance features and real time surveillance of production lines along with incorporation, with suppliers’ systems.

Furthermore there is a growing focus, in the field of operations management towards incorporating practices due to issues. Chinese companies are making investments, in energy resources adopting environmentally friendly manufacturing techniques and improving waste management approaches to support worldwide sustainability objectives.

China is not just advancing technologically; its approach, to skill development is also influencing how operations are managed in the country.. By putting an emphasis on training programs that align with industry requirements China is nurturing a workforce that is well equipped to spur innovation and respond effectively to changing market dynamics.

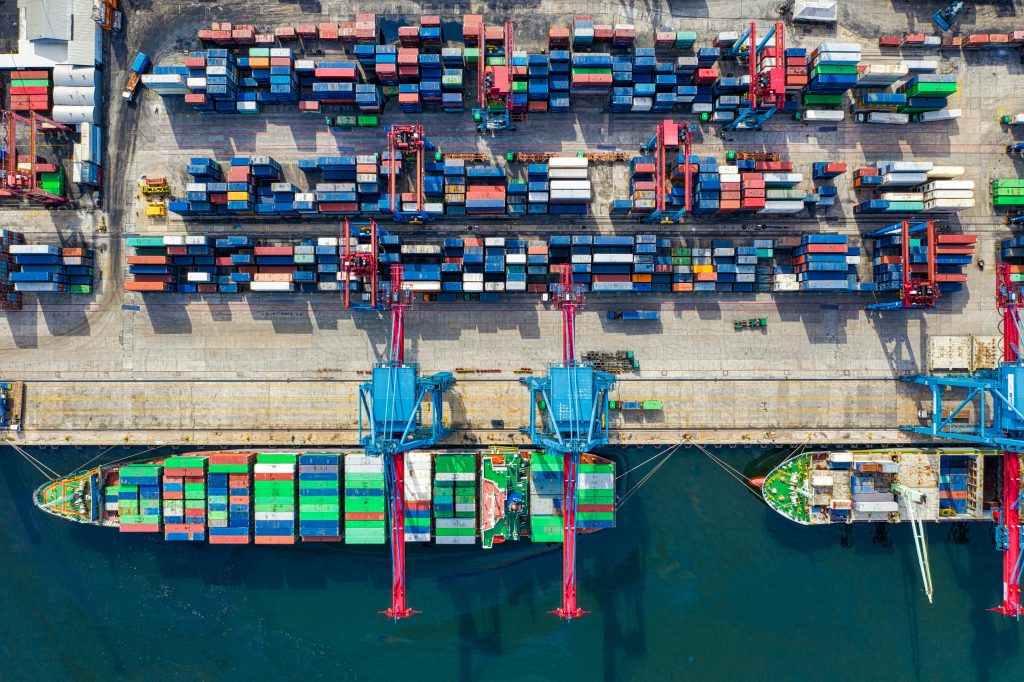

Logistics and Distribution

In the field of managing supply chains smoothly moving goods and materials across the supply chain is crucial It involves making thoughtful choices, about how things are transported and where they are stored to make operations more efficient and cost effective.

Planning and Implementing Effective Logistics

Transportation and Warehousing

Transporting goods plays a role, in managing the logistics of the supply chain industry. Different transportation methods like road transport and air shipping each have their benefits depending on distance and urgency. For example shipping by air is speedy for items while ocean transport is more cost efficient, for deliveries covering long distances.

Warehousing facilities play a pivotal role in the storage and management of inventory. The strategic placement of warehouses enables organizations to minimize transit times, reduce shipping costs, and maintain adequate stock levels to meet consumer demand. Additionally, advanced warehouse management systems leverage automation and data analytics to optimize inventory control, order fulfillment processes, and overall operational efficiency.

Distribution Strategies for Global Supply Chains

Direct Shipping and Cross-Docking

In todays interconnected world efficient distribution plans are vital, for ensuring products can reach locations worldwide smoothly and efficiently People often opt for shipping where goods are sent straight from factories to customers or central hubs reducing the need, for extra handling and storage and speeding up delivery times.

Cross docking is a method that improves distribution by moving products directly to outgoing vehicles without much or any storage time involved.This method helps in cutting down inventory holding expenses. Speeds up the order fulfillment process while boosting the responsiveness of the supply chain.

Logistics Challenges in the China Market

Infrastructure and Regulations

The market, in China poses obstacles because of its large size and varied regulations landscape.The development of infrastructure is key to overcoming these challenges like bridging the connectivity divide between cities and rural areas.Upgrading transportation systems such as roads,railways,port facilities. Airports is vital for improving the effectiveness of the supply chain, as a whole.

In the market it can be quite challenging to navigate all the rules and regulations, in place there is a lot of stuff you need to pay attention to like trade rules customs stuff import export restrictions and paperwork you really need to be careful with everything so your logistics doesn’t get messed up also you got to keep yourself up, to date with all the changing rules and stuff if you want to avoid any compliance issues while doing business in China

Resource Management and Efficiency

Successful supply chain operations rely heavily on management of resources, like materials and labor to operate smoothly and cost effectively while boosting productivity and reducing waste.

Allocating and Utilizing Resources Wisely

Effective resource management is crucial, for efficiency in any industry sector as it involves planning to guarantee access, to necessary materials and optimal use of equipment and skilled labor deployment.

Materials

Efficiently sourcing materials is crucial, for ensuring smooth production operations, in companies to maintain quality standards and cost competitiveness while also managing inventory levels to avoid stockpiling and reduce storage expenses.

Equipment

Efficiently using equipment is vital, for improving production processes. It’s important to stick to maintenance schedules and keep an eye out for any issues with the equipment to avoid downtime and make sure operations run smoothly. Additionally incorporating technologies, like maintenance systems can boost equipment reliability and reduce unexpected breakdowns.

Labor

Effective utilization of workers contributes to optimizing resources by aligning with workforce competency objectives.Enhancing employee skills through job training programs enhances efficiency and boosts productivity.Furthermore scheduling labor, in line, with production needs ensures use of labor without downtime.

Sustainable Resource Management Practices

Incorporating resource management techniques is crucial, for cutting down on waste and improving sustainability, in the supply chain sector.

Reducing Waste

Implementing manufacturing methods helps in reducing waste by spotting activities that don’t add value and improving production processes for efficiency gains. Reducing inventory through, in time inventory control prevents waste buildup and maximizes warehouse space utilization. Moreover incorporating recycling programs, for packaging materials supports waste management strategies.

Enhancing Sustainability

Organizations committed to sustainability integrate renewable energy sources into their operations to reduce reliance on non-renewable resources. Furthermore, adopting eco-friendly packaging solutions minimizes environmental impact throughout the product lifecycle. Embracing circular economy principles promotes the reuse and repurposing of materials, contributing to sustainable resource utilization across the supply chain.

Resource Management Considerations in the China Market

When it comes to dealing with resource management in the market it’s important to grasp the availability of resources and comply with the strict environmental regulations that are common, in the area.

Local Resources

The market, in China provides a variety of resources creating chances for forming partnerships with suppliers within the country’s borders.The use of materials available locally not cuts down on transportation expenses but also encourages working together with stakeholders, in the region to promote sustainable sourcing methods.

Environmental Policies

Ensuring compliance, with regulations is crucial, for businesses operating in the Chinese market. Companies must follow rules regarding emission control waste management practices and sustainable manufacturing methods to align with the countrys goals.

The Role of the China Market in Global Supply Chain Management

China’s Influence on Global Supply Chains

The impact of the market, on supply chains is significant as it functions as a crucial manufacturing center and a vast consumer base at the same time. Being the leading manufacturing economy globally China holds a position in producing and putting together an array of products including electronics, textiles, machinery and other items. Its vast network of suppliers and manufacturers plays a role in ensuring products are readily accessible, across sectors worldwide.

importantly in China a growing middle class community has become a driving force, behind its becoming a major player in the consumer market sector The rising disposable income and changing tastes of Chinese consumers offer attractive prospects for companies aiming to broaden their customer base and benefit from the rising interest, in a variety of products and services.

Navigating the Challenges and Opportunities

In the evolving realm of the Chinese market scenarios companies involved in overseeing supply chains must skillfully address a range of obstacles while leveraging numerous chances, for long term expansion and development.

Adapting Strategies for Success

To succeed in supply chain management, within Chinas market it’s crucial to adjust strategies to fit the countrys characteristics.Focusing on localizing efforts that match tastes and cultural preferences helps build connections with consumers.Moreover collaborating closely with suppliers and distributors improves effectiveness and enables easier entry, into local markets.